The Açominas plant started operations in 1986 and operated for years until it was acquired by GERDAU in 2003. The plant’s product mix consists of slabs, plates, coiled plates, hot rolled sheets and coils, ingots, blooms and billets, medium and heavy structural shapes, and wire rods.

The Gerdau Açominas S.A plant exports its production to more than 40 countries, making it one of Brasil’s largest steel exporters. They have partnered with ZUMBACH again as its trusted supplier of qualitative measuring solutions, specifically the STEELMASTER SMR 100-S3 beginning its installation in January 2022 and completing the installation in September 2023.

At the GERDAU Ouro Branco factory, different types of profiles are being rolled at temperatures between 750°C and 1200°C, ranging between 4.5 and 50mm OD. So it was important to have a precise system of measuring its production to assure quality

control.

To avoid production time and money loss due to quality issues, GERDAU’s Usina de Ouro Branco location needed a system to support quality control on all bars produced with its new rolling mill with three stands that produce wire rods for the automotive (engine spark plugs) and construction (nails) sector.

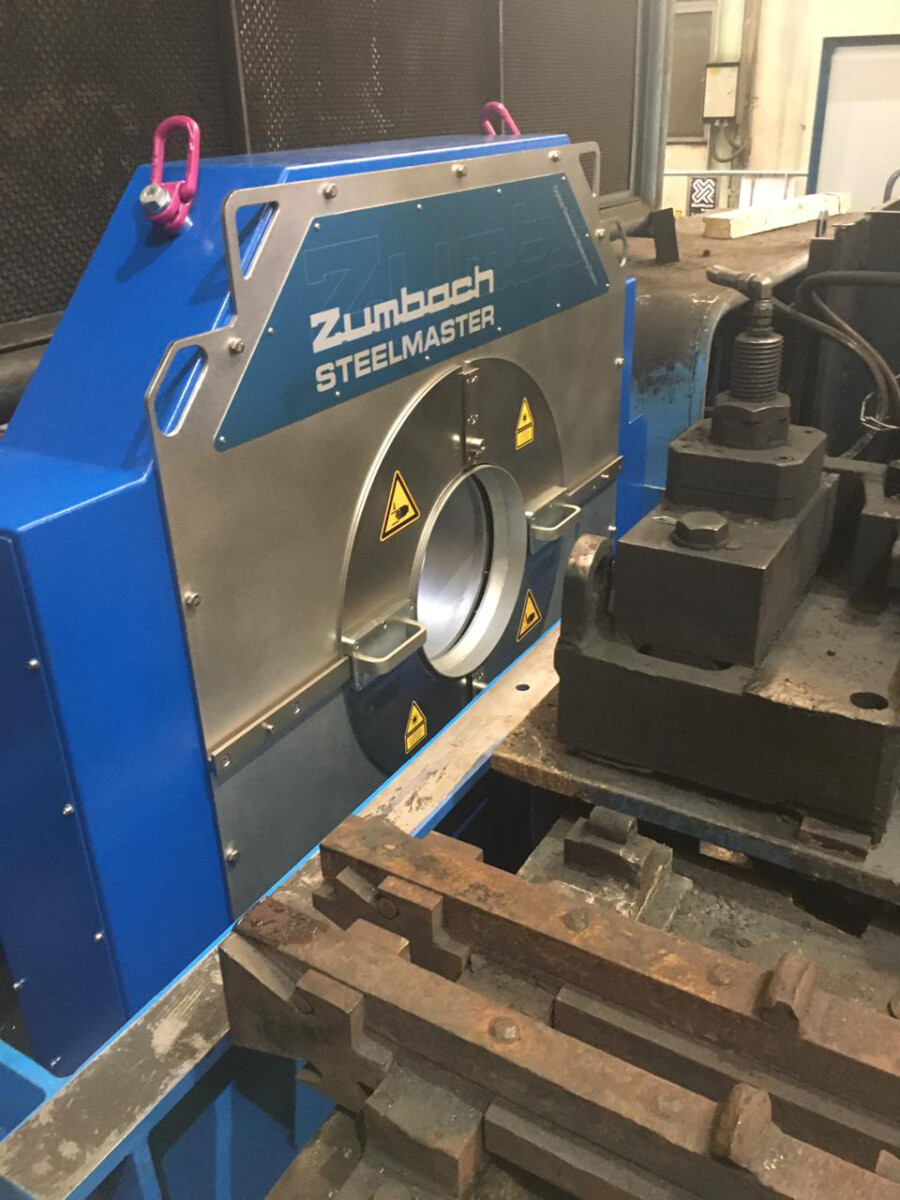

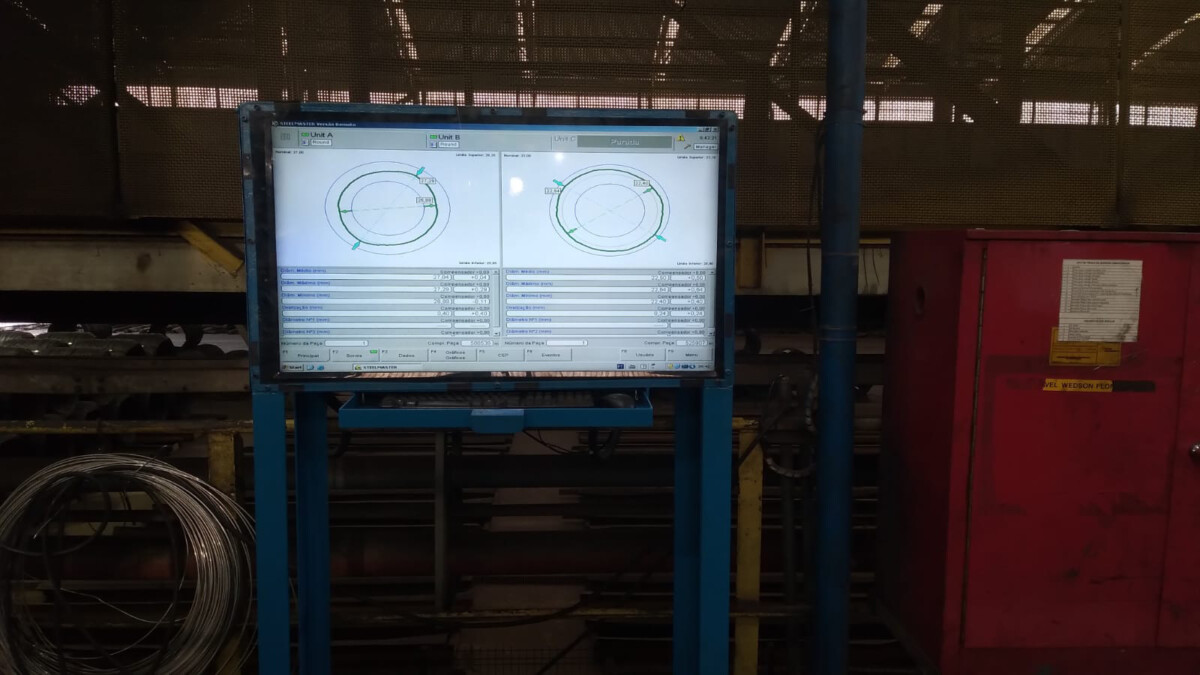

In support of its efforts with quality control, GERDAU installed ZUMBACH’s STEELMASTER SMR 100-S3, a precision laser measuring device for accurately measuring diameter, ovality, height, width, diagonals, and shape variances of hot and cold rolls.

The STEELMASTER is a multigauge with three positions: one after the finishing block, another before the finishing block, and the last in the roughing section. This measuring system is ideal for precise and reliable dimension and shape

measurements in the steel and metal industry. It enables reliable quality control for warm and cold rolling processes.

To accept ZUMBACH equipment, GERDAU requires NR10 / NR12 Certifications, which refer to the protection of the installation and safe use of the system. As expected, ZUMBACH met the equipment certification requirements perfectly.

This wasn’t the first time GERDAU had incorporated ZUMBACH’s systems into its production. GERDAU’s older STEELMASTER system had been in production for over a decade. Due to the facility’s production volume, quality control and uptime were of the most importance.

Given GERDAU’s positive experience with the STEELMASTER before, they were looking to upgrade to the latest technology while preserving some of their knowledge and experience with the system.

ZUMBACH’s systems served the site extremely well and they added additional STEELMASTER positions to increase the visibility of the process and ensure continued maximum productivity from the mill.